Powder Extracts

Powder Extracts

Blue Macaw Flora commercializes several types of powder extracts from plants and fruits of Brazilian flora.

The powder extract also called dry extract is obtained from standardized extraction processes, according to standards required by Brazilian Pharmacopoeia, by spray drying process.

Spray drying

Spray drying or atomization process is a technique to transform liquid solutions into powder extract. Spray drying technique has been widely applied to obtain powder extract with the best technological characteristics and the highest concentration of components with biological activity.

This occurs by atomization of fluid solution, in a drying chamber, where droplets pass through a hot air flow. Transfer of heat and mass during drying is very fast between air and steam films which are around every droplet at a saturation temperature. This technique is adequate for heat-sensitive products, preserving their essential characteristics.

This type of drying process is widely used in food industry, is common to produce powder milk, instant coffee, powder juices, and also very used to produce the capsules of active components in pharmaceutical and phytotherapic industry.

Spray drying is ideal for cases where final product should respect a high specific and reproducible quality standard regarding size and morphology of particles, percentage of residual humidity, density, among other parameters.

This technique allows the removal of water, keeping the quality of dry residue and assuring a higher durability of the product.

Other advantage to use spray drying is that process not only preserves nutritional values of the products but also empowers them, being ideal to food and beverages, pharmaceutical and/or cosmetics industries, among others.

Powder extract sold by Blue Macaw Flora is from raw-materials obtained from approved suppliers and follow a rigorous standardization process which ensures traceability and good environment practices. In addition, the products are supplied with an analysis certificate (which includes physical-chemical analysis, markers dosages and microbiological analysis). Thus, powder extract complies with all specifications and food safety legislation in force. We can also meet determinations of other contaminants, such as pesticides, heavy metals and aflatoxins.

Blue Macaw Flora also makes available the powder extract in different concentration patterns of the active ingredients, according to the customer’s needs.

ACAI

(Euterpe oleracea)

A very known fruit by Brazilian population, mainly by those who look for a healthy diet and rich in energy, açaí is known as a “superfruit”, because of its nutritional properties. Composed of lipids, polyphenols, flavonoids and vitamin, it has a high content of fibers, high concentration of complex B vitamin and anthocyanin (known by its antioxidant activity).

Açaí is the first fruit of a palm tree from Amazon, and in addition to being stimulating, it helps to reduce cholesterol, is anti-aging and helps to lose weight. It is also anti-inflammatory, it helps heart and immunological system health, among many other benefits. Due to presence of flavonoids and vitamin E, it is used in cosmetology, for nutrition and regeneration of skin and hair.

This Brazilian superfruit, in addition to be popularly consumed as a cold cream, it is also very used as a raw-material for food and beverage industry, in nutritional supplements, energy drinks, multivitamin complexes, among many other forms of use.

Powder extract of açaí commercialized by Blue Macaw Flora is standardized in different concentrations and in several levels of polyphenols.

A very known fruit by Brazilian population, mainly by those who look for a healthy diet and rich in energy, açaí is known as a “superfruit”, because of its nutritional properties. Composed of lipids, polyphenols, flavonoids and vitamin, it has a high content of fibers, high concentration of complex B vitamin and anthocyanin (known by its antioxidant activity).

Açaí is the first fruit of a palm tree from Amazon, and in addition to being stimulating, it helps to reduce cholesterol, is anti-aging and helps to lose weight. It is also anti-inflammatory, it helps heart and immunological system health, among many other benefits. Due to presence of flavonoids and vitamin E, it is used in cosmetology, for nutrition and regeneration of skin and hair.

This Brazilian superfruit, in addition to be popularly consumed as a cold cream, it is also very used as a raw-material for food and beverage industry, in nutritional supplements, energy drinks, multivitamin complexes, among many other forms of use.

Powder extract of açaí commercialized by Blue Macaw Flora is standardized in different concentrations and in several levels of polyphenols.

ACEROLA

(Malpighia glabra L.)

Acerola is native fruit from Central America and South America and Brazil is the biggest producer and exporter of the world. It is rich in vitamin C (more than 80% of the quantity found in orange and lemon), vitamin A, B1 (thiamine), B2 (riboflavin), B3 (niacin), calcium, phosphorus and iron, which make acerola an important ally to our health. Among its benefits, we have the prevention of diseases such as flu, muscle weakness and infections, directly helping to boost immunological system and cellular respiration. Because of vitamin C, the fruit acts in the adequate functioning of white blood cells and is also efficient against infectious diseases. Acerola is also used as a supplement to treatment of varied types of cancer.

Acerola powder is used in food and beverage industries, as natural antioxidants and nutritional supplements, in addition to energy drinks, natural juices, cereal bars, yogurts and food supplements.

Acerola extract of Blue Macaw Flora is standardized in different concentrations and in several levels of vitamin C.

CAMU CAMU

(Myrciaria dubia H.B.K)

This little fruit, from the heart of Amazon, is known for being the greatest natural source of vitamin C of the world, with more than a hundred times the amount found in orange, for example. Due to this amount, camu camu is a powerful food and is increasingly gaining the interest of people in Brazil and in the world.

Its benefits are several, among which we can highlight the contribution to immunological system strengthening, improvement of brain functions and increased production of white blood cells The fruit still has detox, anti-inflammatory functions and stimulates cardiac, respiratory and blood functions. Camu camu can also help to improve humor and cognitive balance and, consequently, acts in the prevention of depression.

Camu camu, normally used as a powder and mixed with other fruits, is used in food and beverage industry as an ingredient for juices, ice creams, sweets, energy drinks, cereal bars, yogurts, food supplements and encapsulated phytotherapics or tablets, among other products.

Blue Macaw Flora commercializes dry camu camu extract standardized in different concentration of vitamin C.

This little fruit, from the heart of Amazon, is known for being the greatest natural source of vitamin C of the world, with more than a hundred times the amount found in orange, for example. Due to this amount, camu camu is a powerful food and is increasingly gaining the interest of people in Brazil and in the world.

Its benefits are several, among which we can highlight the contribution to immunological system strengthening, improvement of brain functions and increased production of white blood cells The fruit still has detox, anti-inflammatory functions and stimulates cardiac, respiratory and blood functions. Camu camu can also help to improve humor and cognitive balance and, consequently, acts in the prevention of depression.

Camu camu, normally used as a powder and mixed with other fruits, is used in food and beverage industry as an ingredient for juices, ice creams, sweets, energy drinks, cereal bars, yogurts, food supplements and encapsulated phytotherapics or tablets, among other products.

Blue Macaw Flora commercializes dry camu camu extract standardized in different concentration of vitamin C.

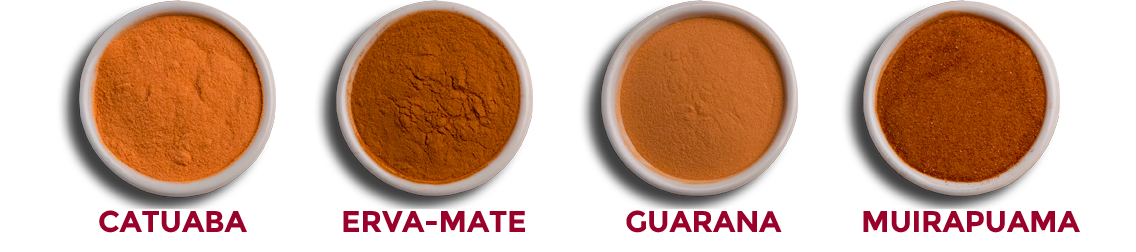

CATUABA

(Trichilia catigua)

Catuaba is a plant found in many regions of Brazil and is famous for its aphrodisiac properties. It is traditionally used to tone, balance and calm down central nervous system and as a general tonic of the body.

It is also consumed to improve sexual function of men and women, being the most popular natural aphrodisiac fruit in Brazil and a subject of study in Europe and in the United States. In addition to being aphrodisiac, the fruit is also antioxidant, anti-anxiety, anti-microbial, diuretic, stimulating, expectorant and vasodilatory. Thus, its use is indicated for people who have bronchitis, neurasthenia, insomnia, depression, excessive nervousness, fatigue, mental and physical breakdown, lack of concentration and memory.

The fruit is commonly used in combination with muirapuama, to boost its aphrodisiac properties. It can also be combined with dry leaves of yerba-mate, to maximize its effect as a sexual stimulator.

Catuaba is used in food and beverage industry as a phytotherapic drug (capsules or tablets) and as a nutritional supplement. It is also in pharmacological and cosmetic industry.

In its portfolio, Blue Macaw Flora makes available powder catuaba extract.

YERBA-MATE

(Ilex paraguariensis)

Very traditional in the south and center-west of the country, as well as Paraguay, Argentina and Uruguay, the yerba-mate originates from the South of the continent and has been used as an energy drink since before the times of American colonization, mainly by Guarani indians of the region where today is the capital of Paraguay, Asunción.

The yerba-mate is well known for its energetic and stimulating power, but the plant’s properties are numerous. It helps in reducing the “bad cholesterol” (LDL) and increasing the “good” (HDL), in preventing heart disease, in metabolic balance and in digestion.

The dried extract of yerba-mate can be used in the beverage and food industry as herbal products, cosmetics and health care products.

Blue Macaw Flora standardizes yerba-mate extract on various levels of caffeine.

Very traditional in the south and center-west of the country, as well as Paraguay, Argentina and Uruguay, the yerba-mate originates from the South of the continent and has been used as an energy drink since before the times of American colonization, mainly by Guarani indians of the region where today is the capital of Paraguay, Asunción.

The yerba-mate is well known for its energetic and stimulating power, but the plant’s properties are numerous. It helps in reducing the “bad cholesterol” (LDL) and increasing the “good” (HDL), in preventing heart disease, in metabolic balance and in digestion.

The dried extract of yerba-mate can be used in the beverage and food industry as herbal products, cosmetics and health care products.

Blue Macaw Flora standardizes yerba-mate extract on various levels of caffeine.

GUARANA

(Paullinia cupana)

Guarana is one of the most known fruits of Brazilian flora, mainly when associated to beverage industry. But its nutritional richness makes it much more versatile. In addition to the use as a basis for beverage, it is also used in food supplements, phytotherapic drugs and even in cosmetics industry.

Original from Brazilian tropical forests and domesticated by Indians, it has always been valued by its energy power, due to high presence of caffeine (amount of 4 to 8% more than in a coffee grain). But the fruit can also be associated to an increased concentration and mental alertness status, fatigue combat, physical resistance growth, and also, can be used as an appetite suppressant and fat burn. Psychopharmacological tests found that guarana can improve memory and humor.

Blue Macaw Flora standardized powder guarana extract in several levels of caffeine.

MUIRAPUAMA

(Ptycopetalum olacoides)

Muirapuama is a native medicinal plant of Brazilian Amazon Forest and popularly known as a powerful natural aphrodisiac fruit to fight several sexual dysfunctions. The fruit can also be used as a tonic to fight nervous disorders, depression and helps to improve neuralgia and blood circulation. Muirapuama still acts in anemia treatment, combat stress and fatigue, improves memory, acts against diarrhea and other intestinal dysfunctions, combat cellulites and helps to ease menopause discomfort and menstrual cramps.

Normally muirapuama is combined with other herbs, such ah Damiana, Guarana and Pfaffia, enhancing its properties and effects. Its powder extract is used in food and beverage industry for composition of energy drinks, as phytotherapic items (in capsules or tablets) nutritional supplements, or even in cosmetics industry.

Blue Macaw Flora makes available in its portfolio the standardized dry muirapuama extract.

Muirapuama is a native medicinal plant of Brazilian Amazon Forest and popularly known as a powerful natural aphrodisiac fruit to fight several sexual dysfunctions. The fruit can also be used as a tonic to fight nervous disorders, depression and helps to improve neuralgia and blood circulation. Muirapuama still acts in anemia treatment, combat stress and fatigue, improves memory, acts against diarrhea and other intestinal dysfunctions, combat cellulites and helps to ease menopause discomfort and menstrual cramps.

Normally muirapuama is combined with other herbs, such ah Damiana, Guarana and Pfaffia, enhancing its properties and effects. Its powder extract is used in food and beverage industry for composition of energy drinks, as phytotherapic items (in capsules or tablets) nutritional supplements, or even in cosmetics industry.

Blue Macaw Flora makes available in its portfolio the standardized dry muirapuama extract.

For more information or request a quote, please contact us.